| Ms.Saba Khan Ph.D. Research Scholar Department of Management G H Raisoni University Saikheda, (M.P.) India |

Abstract

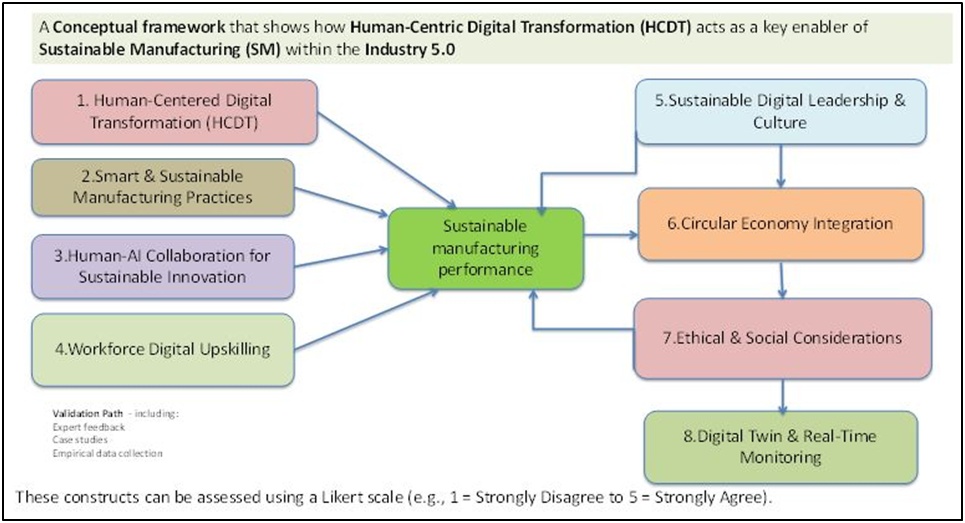

The transition to Industry 5.0 marks a paradigm shift in manufacturing, emphasizing human-centric digital transformation (HCDT) as a pathway to achieving sustainability. This paper explores the challenges and opportunities of embedding sustainability within manufacturing systems through the integration of advanced digital technologies such as artificial intelligence (AI), Internet of Things (IoT), and digital twins. Key barriers include legacy system integration, skill gaps, high implementation costs, and ethical concerns surrounding AI and data privacy. At the same time, significant opportunities arise from enablers such as workforce digital upskilling, sustainable digital leadership, circular economy integration, and human–AI collaboration. Drawing on global case studies and emerging lessons from the Indian manufacturing sector, the paper highlights how Industry 5.0 can align with the United Nations Sustainable Development Goals (SDGs) by fostering environmental stewardship, social equity, and economic resilience. Policy recommendations emphasize the role of governments in providing incentives, regulatory frameworks, and infrastructure, while managerial implications underscore the importance of organizational culture, change management, and measurable sustainability outcomes. The findings contribute to both academic discourse and industrial practice by offering a framework that links HCDT with sustainable manufacturing, guiding firms toward resilience and inclusivity in the digital era.

Keywords

Industry 5.0; Human-Centric Digital Transformation; Sustainable Manufacturing; Circular Economy; Digital Leadership; Human–AI Collaboration; Sustainable Development Goals (SDGs).

Introduction

The Sustainable Development Goals (SDGs) represent a global call to action aimed at eradicating poverty and inequality, safeguarding the environment, and ensuring health, justice, and prosperity for all. Central to this vision is the principle that no one should be left behind. In today’s rapidly evolving industrial landscape, integrating sustainability into business operations is no longer merely an ethical responsibility but has become a strategic necessity. Organizations that prioritize environmental stewardship and social responsibility strengthen their long-term resilience, competitiveness, and contribution to global well-being.

Within this context, the aim of this paper is to examine the challenges that hinder the adoption of sustainable manufacturing in the era of Industry 5.0, while also identifying the enablers that can help overcome these challenges. By doing so, the paper provides valuable insights into both the barriers and opportunities of achieving sustainability through human-centric digital transformation, highlighting the pathway towards a more resilient and inclusive industrial future

The Sustainable Development Goals (SDGs)

The Sustainable Development Goals (SDGs) were born at the United Nations Conference on Sustainable Development in Rio de Janeiro in 2012. The Sustainable Development Goals (SDGs), also known as the Global Goals, The objective was to produce a set of universal goals that meet the urgent environmental, political and economic challenges facing our world.

The five pillars of the Sustainable Development Goals (SDGs) are People, Prosperity, Planet, Peace, and Partnership. These pillars represent the core areas of focus for achieving sustainable development by 2030, Adopted by the United Nations in 2015, the 17 interconnected goals address a broad range of social, economic, and environmental challenges. The SDGs build upon the Millennium Development Goals (MDGs), expanding the scope to include a more comprehensive and integrated approach to sustainable development.

The United Nations’ Sustainable Development Goals (SDGs) provide a universal blueprint for addressing interconnected global challenges. Many of these goals directly align with the agenda of Human-Centric Digital Transformation (HCDT) and Sustainable Manufacturing (SM) within the framework of Industry 5.0. For instance, advancing Decent Work and Economic Growth (SDG 8) is supported by digital transformation initiatives that foster human–AI collaboration, workforce upskilling, and safer working environments. Similarly, Industry, Innovation, and Infrastructure (SDG 9) resonates strongly with the adoption of smart technologies, IoT, and resilient manufacturing networks, enabling industries to innovate sustainably.

Sustainability-oriented practices such as circular economy integration, responsible consumption, and resource efficiency directly contribute to Responsible Consumption and Production (SDG 12), while Climate Action (SDG 13) is reinforced through digital tools that enable real-time monitoring, carbon footprint reduction, and eco-efficient production systems. Furthermore, HCDT places people at the center of transformation, thereby advancing Quality Education (SDG 4) through continuous learning and digital skills, and Gender Equality (SDG 5) by enabling inclusive participation in the digital workforce.

From an environmental perspective, Industry 5.0-driven sustainable manufacturing practices contribute to Life on Land (SDG 15) by reducing waste and supporting biodiversity-friendly production, and Life Below Water (SDG 14) by promoting sustainable supply chains that minimize marine pollution. At the governance level, fostering Peace, Justice, and Strong Institutions (SDG 16) can be linked to ethical AI practices, transparent decision-making, and socially responsible digital leadership. Finally, achieving large-scale transformation requires Partnerships for the Goals (SDG 17), where collaboration between policymakers, academia, and industry becomes vital to accelerate sustainable outcomes.

Thus, by embedding human-centric digitalization into industrial practices, Industry 5.0 not only supports manufacturing competitiveness but also contributes meaningfully to the global SDG agenda.

Sustainable Development: Current Challenges

A key challenge many firms encounter is integrating sustainability into their business models. While owners recognize the benefits of operating more sustainably and aspire to build greener organizations, the shift from traditional practices to sustainable operations is not always easy. As Stewart Udall once said, “Plans to protect air and water, wilderness and wildlife are plans to protect man.” Despite this awareness, businesses often face considerable obstacles in adopting sustainable practices. Let’s look at some of the major challenges.

1. Environmental Challenges

Sustainable development is heavily constrained by environmental pressures such as rising carbon emissions, depletion of natural resources, and biodiversity loss. Although the concept of a circular economy has gained momentum, significant implementation gaps remain, particularly in waste reduction, recycling, and resource efficiency. These environmental issues hinder global efforts to achieve climate targets and long-term ecological balance.

2. Economic Challenges

The transition to sustainability often involves high investment costs in green technologies, renewable energy systems, and sustainable infrastructure. For many firms, especially in developing economies, affordability and competitiveness remain barriers. Companies may perceive sustainability as a cost burden rather than a long-term investment, slowing down adoption. Ensuring that green growth does not compromise economic competitiveness is a major challenge.

3. Social Challenges

Sustainability also carries important social implications. The shift to greener business models can result in workforce displacement, particularly in industries reliant on traditional manufacturing or fossil fuels. Additionally, there are persistent skill gaps in digital and green competencies, which limit the ability of workers to adapt. Sustainable development must also prioritize human well-being, equity, and inclusion to ensure that benefits are widely shared across society.

4. Technological Challenges

Technological innovation is a key enabler of sustainability, but several obstacles persist. Many regions face inadequate infrastructure for renewable energy, smart manufacturing, or sustainable supply chain management. Moreover, the rise of digital technologies introduces new risks such as cybersecurity threats and the ethical implications of artificial intelligence (AI). Addressing these challenges requires responsible deployment of technology to ensure it supports, rather than undermines, sustainability.

Industry 5.0 and Human-Centric Digital Transformation

One of the central themes in Industry 5.0 is its emphasis on human-centric principles, which distinguish it from the previous industry paradigms like Industry 4.0. Varela et al. (2021) discuss how human-centric design principles, which prioritize the well-being of workers and their collaboration with machines, are integrated into manufacturing processes. This contrasts sharply with Industry 4.0’s focus on automation and machine efficiency, where human roles were often marginalized. Wang and Wang (2021) expand on this by discussing how Industry 5.0 offers a more balanced approach that recognizes the importance of human capabilities and creativity in driving innovation alongside technology. This shift in focus is a response to the challenges posed by automation, where job displacement and worker disengagement had become major concerns.

The role of workers in Industry 5.0 is fundamental, as it integrates advanced technologies like artificial intelligence, robotics, and IoT with human input. Günther and Eberhard (2021) argue that robotic process automation can significantly improve both productivity and safety by assisting workers in hazardous or monotonous tasks, but only when the technology is designed with human well-being in mind. Thus, there’s a growing recognition that technology should augment human capabilities rather than replace them entirely.

Sustainability in Industry 5.0

Sustainability is a critical component of Industry 5.0, and Misra et al. (2020) address how sustainable manufacturing is no longer merely about minimizing environmental impact, but also encompasses broader social and economic dimensions. For instance, Kusiak (2020) looks at the role of smart manufacturing and how it leverages digital tools like AI and IoT to reduce waste, enhance resource efficiency, and optimize energy usage. However, Kusiak also notes that smart manufacturing technologies must be applied with a clear focus on sustainability metrics to ensure that their environmental benefits are realized.

The integration of sustainability into Industry 5.0 is not only about using technology to reduce environmental impact but also about creating systems that promote social sustainability. For example, workforce well-being becomes an integral sustainability metric, yet Misra et al. (2020) point out that this area is often underexplored compared to environmental factors like energy use and emissions. This observation indicates that while much attention has been given to the ecological side of sustainability, the social and economic impacts of technology adoption in manufacturing should also be prioritized.

The Role of Digital Technologies

Digital technologies such as IoT, AI, and robotics play a crucial role in shaping the future of manufacturing in Industry 5.0. Atzori, Iera, and Morabito (2010) first introduced the idea of IoT, which enables the connectivity of devices and machines to collect real-time data, optimize processes, and improve resource efficiency. This data-driven approach is fundamental for sustainable practices in manufacturing, as it allows for the precise monitoring of energy usage, waste, and emissions.

Brettel et al. (2014) highlighted how digitalization and virtualization technologies enhance the manufacturing landscape by providing the ability to simulate and test systems digitally before implementing them physically. This reduces resource waste and operational costs, aligning with sustainability goals. However, these technologies also present challenges, particularly in integrating them with existing infrastructure and ensuring they are accessible to all levels of employees, which has been a barrier to widespread adoption in many industries.

Challenges in Implementing Sustainable Manufacturing through Human-Centric Digital Transformation (HCDT):

1. Human-Centric Digital Transformation (HCDT):

Human-Centric Digital Transformation emphasizes creating reliable and accessible digital infrastructure that includes IoT, AI, cloud systems, and smart sensors. A major challenge is integrating existing legacy systems with modern digital platforms while ensuring seamless interoperability. Maintaining high data quality is critical to support analytics and automation, whereas avoiding vendor lock-in remains essential to preserve flexibility. Additionally, organizations face the ongoing risk of rapid technology obsolescence, which demands continuous adaptation and strategic foresight.

2. Sustainable Digital Leadership (SDL):

Sustainable Digital Leadership focuses on establishing a clear vision for digital transformation initiatives that align with sustainability objectives. Strong top-management commitment is vital to drive meaningful progress, supported by the allocation of adequate resources for sustainability-driven digital projects. Leaders must effectively communicate long-term goals across the organization to ensure shared understanding and alignment. Moreover, embedding ethical and responsible technology practices into leadership decisions is crucial to balance innovation with sustainability and societal well-being.

3. Circular Economy Integration (CEI):

Organizations often struggle with low awareness of circular economy principles and inadequate systems for recycling, reuse, or waste management. Many firms also face supply chain limitations that hinder the adoption of closed-loop practices, making it difficult to align with sustainability goals.

4. Ethical & Social Considerations (ESC):

Cybersecurity vulnerabilities and data privacy issues create major risks in digital environments. Moreover, ethical dilemmas associated with AI decision-making and concerns over employee well-being further complicate the transition toward sustainability.

5. Human-Centric Digital Transformation (HCDT):

A lack of reliable digital infrastructure and difficulties in integrating legacy systems with advanced technologies are persistent challenges. Poor data quality and the absence of standardized digital frameworks also restrict effective transformation.

6. Human–AI Collaboration (HAIS):

Employee distrust in AI systems, coupled with the lack of transparency in algorithmic decision-making, hampers collaboration. Fear of job displacement further intensifies resistance to adopting AI-enabled sustainable practices.

7. Organizational Culture (OC):

Resistance to change among employees and leadership remains a critical barrier. Traditional mindsets, hierarchical structures, and risk-averse attitudes slow down the adoption of innovative and sustainable practices.

8. Smart & Sustainable Manufacturing Practices (SSMP):

High costs associated with implementing energy-efficient technologies and smart manufacturing tools discourage investment. Limited access to green supply chain networks and technical uncertainties add to the complexity of adoption.

9. Sustainable Digital Leadership (SDL):

The absence of clear vision and strategic direction from leadership is a major obstacle. Leaders often lack the knowledge, commitment, or long-term perspective necessary to drive sustainable digital initiatives effectively.

10. Workforce Digital Upskilling (WDU):

A shortage of employees with advanced digital skills poses a significant challenge. Skill gaps in areas like AI, IoT, and data analytics slow down transformation efforts, while inadequate training mechanisms exacerbate the problem.

Key Enablers of Human Centric Digital Transformation (HCDT) for Sustainable Manufacturing

1. Human-Centric Digital Transformation (HCDT)

Human-Centric Digital Transformation is enabled by advanced digital infrastructure that integrates IoT, AI, cloud platforms, and smart sensors. A critical enabler lies in establishing interoperable IT systems that ensure seamless connectivity and reliable data accuracy. Real-time analytics and monitoring systems provide timely insights for effective operational decision-making, while predictive and preventive maintenance supported by digital tools enhances equipment reliability and reduces downtime. Moreover, a scalable technology architecture is essential to accommodate future innovations and sustain long-term adaptability.

2. Sustainable Digital Leadership (SDL)

Sustainable Digital Leadership is driven by a clear strategic vision that harmonizes digital transformation with sustainability objectives. Strong top-management support for technology adoption and innovation ensures alignment of organizational priorities. Leaders play a crucial role in embedding ethical practices within digital initiatives and committing to the responsible use of emerging technologies. The allocation of sufficient resources supports the achievement of long-term digital–sustainability goals, while employee involvement in strategic decision-making fosters inclusivity, accountability, and shared ownership of outcomes.

3. Workforce Digital Upskilling (WDU)

Workforce Digital Upskilling serves as a cornerstone for enabling Industry 5.0 by equipping employees with the skills necessary to thrive in digitally transformed environments. Continuous training programs on Industry 5.0 tools and techniques help employees remain future-ready, supported by accessible learning platforms that promote digital skill development. Incentive mechanisms encourage employees to acquire emerging technological competencies, while training initiatives tailored to specific job roles and technologies ensure practical relevance. Regular assessment of digital competency levels further strengthens organizational readiness and guides targeted upskilling efforts.

4. Human–AI Collaboration (HAIS)

Human–AI Collaboration is enabled through platforms designed for seamless human–machine interaction. AI tools play a pivotal role in enhancing employee productivity and supporting effective decision-making. The integration of AI into creative problem-solving and innovation processes expands organizational capabilities beyond traditional methods. To ensure inclusivity, user-friendly AI interfaces cater to employees across varying skill levels. Transparent AI processes further build trust among employees, strengthening adoption and fostering collaboration between humans and intelligent systems.

5. Smart & Sustainable Manufacturing Practices (SSMP)

Smart and Sustainable Manufacturing Practices focus on integrating sustainability into core production systems. Energy-efficient processes and automation technologies not only improve product quality but also reduce material and energy waste. Sustainable sourcing practices ensure responsible procurement of raw materials, while eco-friendly product design emphasizes recyclability and circularity. Continuous improvement programs drive better environmental performance, positioning sustainable practices as an integral part of operational excellence.

6. Circular Economy Integration (CEI)

Circular Economy Integration is achieved through systems that enable reuse, recycling, and remanufacturing across the value chain. Partnerships with supply chain actors strengthen material recovery and support closed-loop processes. Operational strategies incorporate waste reduction targets, while lifecycle assessments provide insights into environmental impacts of products and processes. Incentives for customers to return or recycle products further promote resource efficiency and extend product lifecycles.

7. Organizational Culture (OC)

A supportive organizational culture is a key enabler of digital transformation and sustainability. Cross-functional collaboration across departments fosters knowledge sharing and integrated solutions, while change management initiatives ensure smooth adaptation to technological shifts. Employee participation in innovation projects strengthens creativity and engagement, while openness to experimentation and calculated risk-taking encourages a culture of continuous improvement. Organizational values aligned with digitalization and sustainability goals further consolidate long-term transformation efforts.

8. Ethical & Social Considerations (ESC)

Ethical and social considerations serve as critical enablers in ensuring responsible digital transformation. Policies safeguarding data privacy and cybersecurity protect stakeholders, while initiatives promoting equal access to digital tools ensure inclusivity across the workforce. Ethical guidelines guide the deployment of AI and automation, minimizing potential risks and biases. Additionally, diversity-focused initiatives support fair participation in technological adoption. Evaluating the social impact of major technology projects helps organizations balance innovation with responsibility toward people and society.

Case Insights and Practical Examples-

Global Initiatives and Industry Best Practices

Globally, several firms are pioneering human-centric digital transformation aligned with sustainability. For example, Siemens in Germany has integrated Digital Twin technology and predictive maintenance, enabling real-time monitoring and reduced resource wastage. Toyota in Japan demonstrates how lean manufacturing can be combined with smart automation to enhance product quality while minimizing environmental impact. Similarly, Unilever has implemented circular economy principles by leveraging digital supply chain optimization to minimize waste and enhance material recovery. Tesla in the United States exemplifies the convergence of AI, automation, and eco-friendly product design, thereby showcasing how digital transformation can accelerate sustainable manufacturing practices. These global initiatives provide valuable benchmarks for other nations and industries aspiring to align with Industry 5.0.

Indian Manufacturing Sector: Anticipated Lessons

While India is still in the early stages of Industry 5.0 adoption, several initiatives indicate promising directions. Government programs such as Digital India, Make in India, and National Manufacturing Policy are laying the foundation for digital transformation across sectors. Indian manufacturers are increasingly exploring IoT-enabled monitoring systems, automation in production lines, and digital platforms for supply chain integration. Anticipated lessons from the Indian context highlight the importance of workforce digital upskilling to bridge skill gaps, the need for strong digital leadership to overcome resource constraints, and the role of circular economy integration in sectors such as textiles and automotive. Though challenges persist—such as legacy system integration, infrastructure gaps, and limited investment capacity—these lessons indicate that India is positioned to benefit significantly from adopting human-centric and sustainable digital transformation practices in the near future.

Policy and Managerial Implications

Policy Implications

Policymakers play a critical role in creating an enabling environment for Human-Centric Digital Transformation (HCDT) and Sustainable Manufacturing (SM). Governments should design incentive structures, such as tax benefits, subsidies, or grants, to encourage industries to adopt eco-friendly technologies, circular economy practices, and digital solutions aligned with Industry 5.0. Developing regulatory frameworks that balance innovation with data privacy, cybersecurity, and ethical AI use is essential for building trust. Policymakers should also prioritize infrastructure development, including reliable broadband connectivity, cloud facilities, and smart logistics systems, particularly in developing economies where digital readiness varies. Furthermore, national-level training and certification programs are needed to build a digitally skilled workforce, reducing resistance to technological adoption and ensuring inclusivity across industries.

Managerial Implications

For managers, the key challenge lies in translating digital transformation into measurable sustainability outcomes. Organizations must prioritize workforce digital upskilling by integrating continuous learning programs tailored to Industry 5.0 tools, AI collaboration, and sustainable manufacturing practices. Managers should establish sustainability Key Performance Indicators (KPIs)—such as carbon reduction, energy efficiency, waste minimization, and employee well-being—to track progress and align business goals with the UN Sustainable Development Goals (SDGs). Moreover, embedding ethical and human-centric principles into digital strategy is crucial to foster trust and employee acceptance. Managers should also focus on change management and organizational culture, ensuring cross-functional collaboration and inclusivity. By aligning digital initiatives with long-term sustainability strategies, leaders can enhance competitiveness while contributing positively to environmental and social outcomes

Conclusion

The transition toward Industry 5.0 highlights both challenges and opportunities for achieving sustainable manufacturing through Human-Centric Digital Transformation (HCDT). On one hand, organizations face barriers such as legacy system integration, data quality concerns, skill gaps, and ethical considerations in AI deployment. On the other hand, the opportunities offered by digital technologies—ranging from real-time analytics, predictive maintenance, and AI-driven decision-making to circular economy integration and workforce empowerment—present a transformative pathway toward sustainability.

The chapter emphasizes the need to integrate human-centric digitalization into broader sustainable development strategies. By embedding ethical leadership, digital upskilling, collaborative organizational culture, and sustainable manufacturing practices, firms can simultaneously enhance competitiveness and contribute to environmental stewardship, social equity, and economic resilience. Importantly, this alignment directly supports the United Nations Sustainable Development Goals (SDGs), ensuring that digital transformation is not only technologically advanced but also socially responsible and environmentally sustainable.

Future Research Directions

While this chapter provides conceptual clarity on the enablers, challenges, and policy implications of HCDT in sustainable manufacturing, empirical research is still evolving. Future studies could validate the proposed framework through quantitative methods such as Structural Equation Modeling (SEM) or multi-criteria decision-making approaches (AHP, ISM, Fuzzy methods). Comparative case studies across industries and geographies could provide deeper insights into contextual drivers of transformation. Additionally, research should explore the long-term social impacts of human–AI collaboration, workforce adaptation, and circular economy practices, particularly in emerging economies. Such directions will not only strengthen academic discourse but also provide actionable knowledge for policymakers and practitioners in navigating the era of Industry 5.

References:

- European Commission. (2021). Industry 5.0: Towards a sustainable, human-centric and resilient European industry. Brussels: Directorate-General for Research and Innovation.

- Kagermann, H., Wahlster, W., & Helbig, J. (2013). Recommendations for implementing the strategic initiative INDUSTRIE 4.0. Final report of the Industrie 4.0 Working Group. Acatech.

- Nahavandi, S. (2019). Industry 5.0—A human-centric solution. Sustainability, 11(16), 4371. https://doi.org/10.3390/su11164371

- Romero, D., Stahre, J., Wuest, T., & Noran, O. (2022). Industry 5.0: Towards a new paradigm for resilient, sustainable, and human-centric production. Manufacturing Letters, 32, 49–56. https://doi.org/10.1016/j.mfglet.2022.05.002

- United Nations. (2015). Transforming our world: The 2030 Agenda for Sustainable Development. United Nations General Assembly.

- Xu, L. D., Xu, E. L., & Li, L. (2018). Industry 4.0: State of the art and future trends. International Journal of Production Research, 56(8), 2941–2962. https://doi.org/10.1080/00207543.2018.1444806

- Zheng, P., Sang, Z., Zhong, R. Y., Liu, Y., Liu, C., Xu, X., … Xu, C. (2018). Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Frontiers of Mechanical Engineering, 13(2), 137–150. https://doi.org/10.1007/s11465-018-0499-5

- Zolotova, I., & Oliveira, A. (2021). Human-centric digital transformation in Industry 5.0. In Proceedings of the International Conference on Industry 4.0 and Smart Manufacturing (ISM 2021) (pp. 101–107). Springer